MG12 MG1S20 Unbalanced Pump Mechanical Seal 100mm G9 BP Shaft

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Model | MG12 MG1S20 | Speciflcation | Shaft Hole 10mm-100mm |

|---|---|---|---|

| Material | CAR CER SSIC TC NBR EPDM | Usage | Unbalanced |

| Traemark | Bergman | Origin | Guangzhou, China |

| Highlight | MG12 Pump Mechanical Seal,MG1S20 Pump Mechanical Seal,G9 pump shaft seal |

||

Unbalanced Burgmann Mechanical Seal MG12 MG1S20 100mm G9 BP For Stock Pumps

Mechanical Seal Type Burgman MG12 MG1S20 Pump Mechanical Seal G9 BP

Model NO.

MG1S20

Type

MG12

Balance

Unbalanced

Rotary Ring

Ceramic/Sic

Stationary Ring

Plastic Carbon/Carbon/Sic

Spring

SUS304/SUS316

Secondary Seal

NBR/EPDM/HNBR/

Trademark

Bergman

Transport Package

Carton

Specification

12mm to 100mm

Origin

China

HS Code

84842000

ELASTOMER BELLOW MG12 MG1S20 SERIES MECHANICAL SEALS

1.Applicable Range:

|

Pressure in seal chamber: |

0-0.8MPa |

|

Temperature in the seal chamber: |

-25ºC-----200ºC |

|

Linear Velocity: |

≤ 10m/s |

|

Medium: |

water,polluted water,oil and minor corrosive liquid. |

|

Static ring code: |

G60 G6 G4 G9 |

2.Features:

| For plain shaft |

| Elastomer bellows rotating |

| Independent direction of rotation |

| Shaft protection over entire seal length |

| High flexibility due to wide offer on materials |

| Dimension adaptions and additional seats available |

3.Applications:

Process industry

Chemical industry

Pulp and paper industry

Water and waste water technology

Stock pumps

Circulating pumps

Submersible pumps

Water and waster water pumps

4.Materials:

Stationary Ring: , Ni-binder Tungsten Carbide, Silicon Carbide Reaction Bonded, Ceramic(Alumina), Silicon Carbide Sintered Pressureless

Rotary Ring: Resin Impregnated Carbon Graphite(), Antimony Impreg. Carbon Graphite, Silicon Carbide Sintered Pressureless, Silicon Carbide Reaction Bonded Secondary Seal: Fluorocarbon Rubber(), Nitrile(NBR), Ethylene Propylene(EPDM)

|

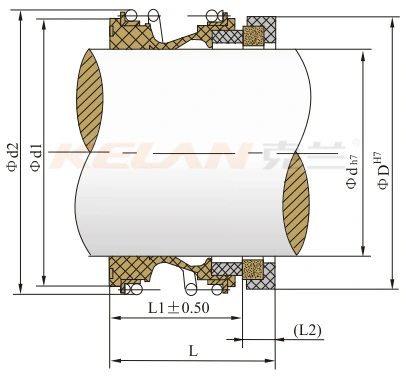

Model(mm) |

d |

d1 |

d2 |

D |

L |

L1 |

L2 |

|

MG12-14 |

14 |

26.5 |

29.0 |

25 |

23.6 |

17.0 |

6.6 |

|

MG12-18 |

18 |

29.0 |

32.0 |

33 |

27.0 |

19.5 |

7.5 |

|

MG12-20 |

20 |

33.0 |

38.0 |

35 |

29.0 |

21.5 |

7.5 |

|

MG12-25 |

25 |

38.0 |

42.5 |

40 |

30.5 |

23.0 |

7.5 |

|

MG12-30 |

30 |

44.0 |

49.0 |

45 |

34.0 |

26.5 |

7.5 |

|

MG12-35 |

35 |

50.0 |

57.0 |

50 |

36.0 |

28.5 |

7.5 |

|

MG12-40 |

40 |

55.0 |

62.0 |

58 |

39.0 |

30.0 |

9.0 |

|

MG12-45 |

45 |

60.0 |

68.0 |

63 |

39.0 |

30.0 |

9.0 |

|

MG12-50 |

50 |

65.0 |

74.0 |

70 |

40.0 |

30.5 |

9.5 |

|

MG12-55 |

55 |

72.0 |

81.0 |

75 |

46.0 |

35.0 |

11.0 |

|

MG12-60 |

60 |

79.0 |

88.5 |

80 |

49.0 |

38.0 |

11.0 |

|

MG12-65 |

65 |

84.0 |

93.5 |

85 |

51.0 |

40.0 |

11.0 |

|

MG12-70 |

70 |

90.0 |

99.5 |

92 |

51.5 |

40.0 |

11.5 |

|

MG12-75 |

75 |

95.0 |

107.0 |

97 |

51.5 |

40.0 |

11.5 |

|

MG12-80 |

80 |

100.0 |

112.0 |

105 |

52.0 |

40.0 |

12.0 |

|

MG12-85 |

85 |

107.0 |

120.0 |

110 |

55.0 |

41.0 |

14.0 |

|

MG12-90 |

90 |

114.0 |

127.0 |

115 |

59.0 |

45.0 |

14.0 |

|

MG12-95 |

95 |

119.0 |

132.0 |

120 |

60.0 |

46.0 |

14.0 |

|

MG12-100 |

100 |

124.0 |

137.0 |

125 |

61.0 |

47.0 |

14.0 |

![]()

![]()

![]()

![]()

Fixing and Applying Directions of Mechanical Seals

1. When installing the mechanical seals,the shaft(shaft sleeve),seal chamber,seal face as well as the mechanical seal

must be cleaned in order to keep from any medium to sealing part.

2. When conveying medium of over high or low temperature,with medium which are easy catch fire,easy for explosion.

Related mechanical seal standards must be referred to take appropriate measures such as quench,rinsing,coolong and

filtrating.

3. Appropricate lubrication must be choosen when mechanical seal is installed.The installment size of the mechanical

seal must be guaranteed to the installment instruction.

4. Before the machine starts running,the hermetic compartment shall be full of medium and well lubricated.Dry friction

which may lead to the damage of the air-tightness is strict forbidden.